An exploration of improving the performance of metal rolling bearings

Abstract:

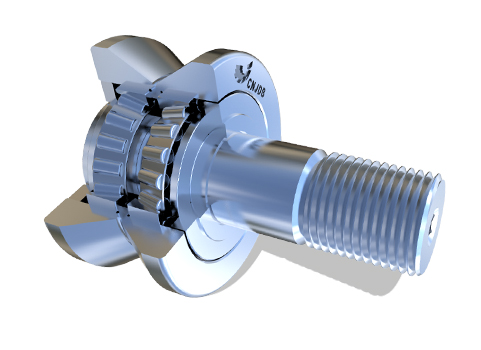

Metal rolling bearings are an essential part of the steel production process, and their performance directly affects the efficiency and quality of the forging machine. Through the analysis of the failure reasons of metal rolling bearings, this paper proposes an optimization scheme for improving the performance of metal rolling bearings, including improving material properties, optimizing the processing techniques, and improving the bearing design.

1. Introduction

Metal rolling bearings are one of the most important bearings in the steel production process, used to support the rolling mill and bear large loads and high friction. Due to the harsh working environment of metal rolling bearings, their performance is often affected by factors such as materials, processing techniques, and operating conditions, leading to failure. Therefore, this paper will focus on improving the performance of metal rolling bearings to reduce their failure risk.

2. Failure reasons analysis of metal rolling bearings

Metal rolling bearings may fail due to various reasons, including material quality, processing techniques, and operating conditions.

(1) Material quality issues

The working environment of metal rolling bearings is harsh, and they are often exposed to high loads, high friction, and high temperatures, which can cause the materials to degrade, fatigue, and become harder, leading to bearings failure.

(2) Processing technique issues

The processing techniques of metal rolling bearings have a significant impact on their performance. If the processing techniques are not standardized, such as insufficient heat treatment, too fast cooling, or poor surface finish, it can lead to problems such as surface roughness, dimensional accuracy, and poor performance, which can affect the bearings" performance.

(3) Operating conditions issues

The operating conditions of metal rolling bearings, such as working temperature and humidity, also have an impact on their performance. If the operating conditions do not meet the performance requirements of the bearings, failure is likely to occur.

3. Optimization scheme for improving the performance of metal rolling bearings

(1) Improving material properties

The materials used for metal rolling bearings should have high wear resistance, high strength, and high corrosion resistance to withstand the high loads, high temperatures, and forging process of rolling mills. At the same time, the materials should have appropriate hardness and wear resistance to improve their performance.

(2) Optimizing processing techniques

The processing techniques of metal rolling bearings should control the processing temperature and cooling rate to avoid overly aggressive processing that leads to surface roughness. In addition, the dimensions and surface quality of the bearings should be strictly controlled to ensure their performance meets the requirements.

(3) Improving bearing design

The design of metal rolling bearings should be optimized according to the operating conditions and requirements. The materials, structure, and working positioning should be selected to improve the bearing capacity, stiffness, and stability.

4. Conclusion

Improving the performance of metal rolling bearings is a crucial step for ensuring the smooth operation of steel production processes. Through measures such as improving material properties, optimizing processing techniques, and improving bearing design, the performance of metal rolling bearings can be effectively improved, reducing the risk of failure.